Erjin: Where Technology and Printing Aesthetics Ensure Every Aluminum Can is Reborn

At Erjin, we firmly believe that a superior packaging can is more than just a container for beverages—it must also embody the brand’s commitment to the environment and the future of our planet.

From the precise forming of a high-strength aluminum coil, to the custom printing shining on the shelf, and finally to the “rebirth” within the efficient recycling system, every Erjin aluminum can is a perfect testament to sustainable development and innovative craftsmanship. We are dedicated to making the journey of every can a benchmark for green circular packaging in the industry.

I. From Aluminum Coil to Can Body: Erjin’s Precision Engineering and Lightweighting Principle

Erjin’s aluminum can manufacturing begins with a roll of high-strength 3104 aluminum alloy strip. This is not just cold metal, but the “sustainable packaging seed” we infuse with life.

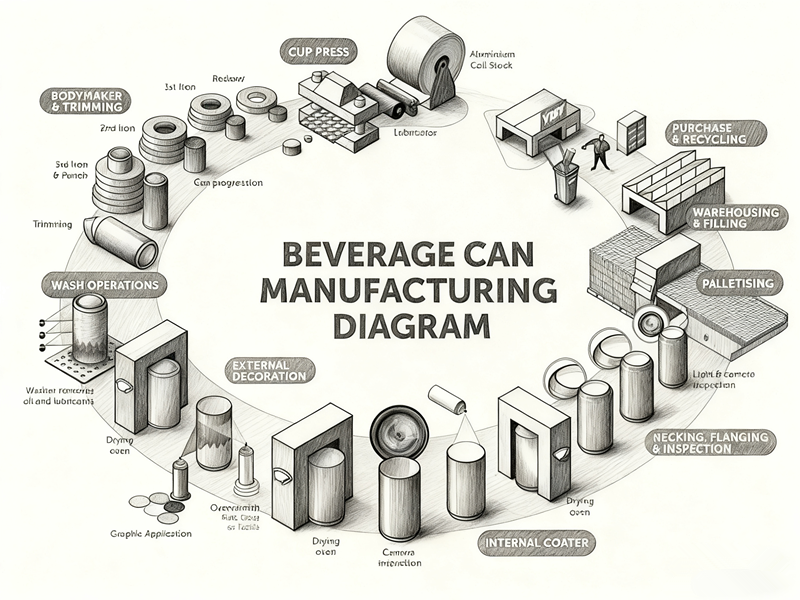

Core Process: Cup Pressing and Blank Uniformity

The aluminum strip is stamped into shallow, round cup blanks using a high-precision cupping press. Every press determines the flatness and forming quality of the subsequent can body. We ensure the uniformity of the blank—the starting point for achieving ultimate lightweighting and structural stability.

Proprietary Technology: Deep Drawing, Ironing, and Weight Reduction

The blank enters multi-stage deep drawing equipment and is “drawn up” and “thinned” using Deep Drawing & Ironing (DWI) technology, achieving the balance of being lightweight yet robust.

- Erjin’s Proprietary Drawing Technology: Our patented technology ensures precise control over the can wall thickness. While guaranteeing high pressure resistance, it successfully achieves a 15% weight reduction, significantly lowering raw material consumption.

Structural Guarantee: Domed Bottom and Precision Trimming

Erjin’s unique “Anti-Pressure Dome” design ensures the can bottom remains stable when enduring the pressure of carbonated beverages. This is followed by precision trimming, guaranteeing every can body is consistent in height and the rim is smooth and burr-free.

- Erjin Quality Standard: We demand extremely high precision for the can opening, with an error margin of less than 0.1mm, laying the foundation for a perfect seal.

II. Can Body Renewal: From Bare Metal to Custom Brand Showcase

At Erjin, we give the aluminum can its “soul.” It is not just a cold metal container, but the first visual dialogue between the brand and the consumer.

Rigorous Process: Six Stages of Washing and High-Precision Printing Adhesion

To ensure printing adhesion and internal cleanliness, the can body undergoes a rigorous process of six washes and drying cycles, completely removing oil and micro-dust. It then enters the high-speed printing machine, utilizing imported inks and a precision registration system to accurately reproduce brand colors and patterns.

Innovative Printing Technology: Enhancing Brand Texture and Experience

Erjin’s printing center boasts 4-to-8 color high-speed printing lines, capable of meeting various brand customization needs:

- Glossy: Makes the brand shine brightly on the shelf.

- Matte: Highlights the packaging’s premium feel and texture.

- White Base: Ensures pure color reproduction fidelity.

- Tactile Printing: Unique textures allow consumers to “feel” the brand, enhancing the interactive experience.

Cost Optimization: Necking and Precision Inspection

Erjin employs a multi-stage necking die system to progressively reduce the can opening diameter, perfectly balancing lightweighting with airtightness.

- Material & Energy Saving: Our small lid diameter design can save clients 8% in raw material costs, reflecting efficient cost control.

- Precision Inspection: Optical inspection systems comprehensively evaluate every can opening, ensuring perfect compliance with sealing standards.

III. The Art of Lid and Seal: The “Last Millimeter” of Beverage Safety Assurance

Though small, the can lid dictates the product’s opening experience and food safety quality. At Erjin, this step is a highly precise engineering process.

Lid Forming and Secure Riveting

The can end is made of high-strength 5182 aluminum alloy strip, stamped, sprayed, baked, and then riveted with the tab. Erjin’s automated tab riveting process ensures smooth and effortless opening, effectively preventing the annoying issue of a “broken tab,” protecting the brand’s first-sip experience in every detail.

Double Seaming: The Safety Pressure Standard

After the beverage is filled, Erjin uses a Double Seaming process to ensure ultimate airtightness:

- First Operation: The lid edge is initially curled with the can mouth flange.

- Second Operation: A high-strength seal is formed, capable of withstanding pressures up to 90 psi, sufficient for all carbonated beverages.

- Erjin Safety Standard: Our cans undergo 100% helium leak detection, the highest commitment to ensuring beverage safety and preventing leakage.

IV. Green Regeneration: Enabling Every Aluminum Can to be Efficiently “Reborn”

The journey of an Erjin aluminum can does not end with consumption. We deeply believe that sustainability is a closed-loop responsibility, integrated from the very start of the design phase.

Recycling System and Low-Energy Smelting

Empty cans are collected, compressed, and delivered to recycling centers. In high-temperature furnaces, they are first treated to remove inks and internal lacquer, then the scrap aluminum is melted into liquid metal.

- Erjin Green Process Core: Using recycled aluminum consumes only 5% of the energy required to produce primary aluminum, achieving significant energy saving and low carbon emissions.

Recasting and Rebirth: Achieving a 60-Day Fast Cycle

The molten aluminum is cast into ingots, rolled into new aluminum sheets, and then into coils, re-entering the can manufacturing plant. Within the Erjin system, an old can can return to the market in as little as 60 days.

Erjin’s Green Commitment: Supporting Brands in Achieving Carbon Neutrality

- High Recyclability Materials: Utilizing environmentally friendly 3104/5182 alloys.

- Eco-Friendly Printing System: Using low-VOC inks and energy-efficient curing systems.

- Circular System: Ensuring full process traceability to assist brands in reaching their carbon neutrality goals.

Conclusion: Erjin – Making Packaging an Extension of Brand Temperament The aluminum can’s complete life cycle journey is the perfect intersection of Erjin’s craftsmanship, environmental ethos, and aesthetics. From forming to printing, from sealing to rebirth, every step embodies our persistence in quality and respect for the planet.

Choose Erjin’s customized can printing technology to give your brand more texture and make the world lighter.

Start Your Brand Customization Journey: 【Erjin Custom Aluminum Cans | Efficient, Eco-Friendly, High-Quality Packaging Solutions】 Contact us now to receive an exclusive printing proposal and technical evaluation.E-mail:info@erjinpack.com

Post time: Nov-12-2025