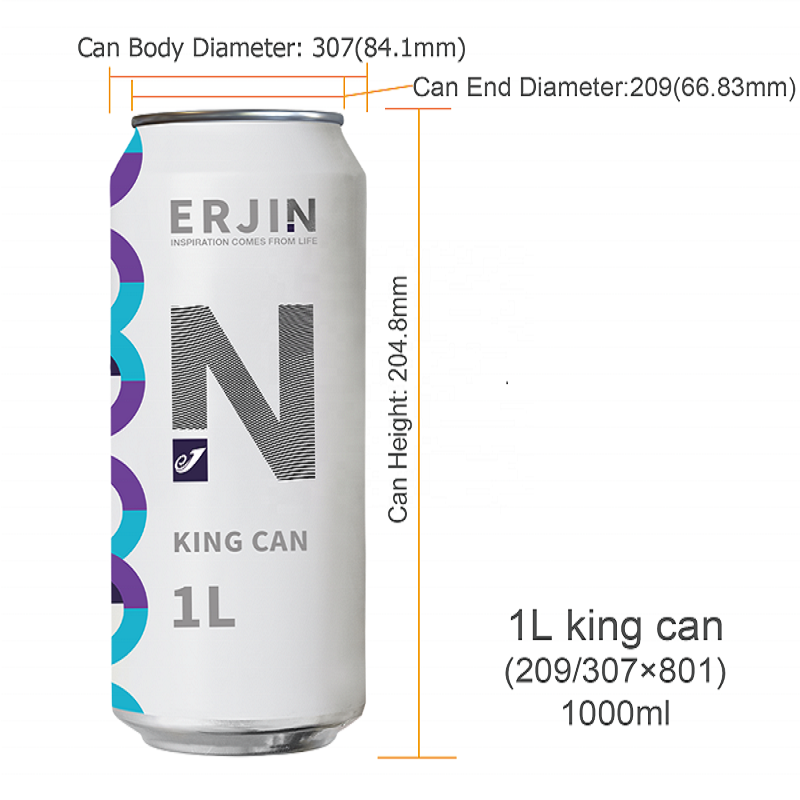

Customized 1L 1 liter 100cc Soda Juice food grade printed Aluminium beer Beverage Can

Product Description

Colors : Plain or customized printing(max 7 colors)

Inner coating :Epoxy

MOQ ![]() lain 120,000 Printed /250,000(each SKU) /Retort 300,000

lain 120,000 Printed /250,000(each SKU) /Retort 300,000

Delivery Time: 20-25 days after payment

Payment Term : TT

Usage: beer, juice, soda, carbonated drinks, etc.

aluminum can pallet size:1420x1120x2466mm

Erjin 1L Custom Aluminum Can: Key Selling Points & Advantages

Based on the link provided (showcasing a 1 Liter / 1000ml large-capacity custom printed aluminum can), here are the core selling points and advantages of this product, categorized by function, design, and structure.

1. Innovative Capacity & Market Differentiation (H2)

-

Selling Point: “Size is the Advantage.” While the market is saturated with 330ml or 500ml options, the 1L format offers a unique option for family sharing, bulk consumption, or high-intensity scenarios (like outdoor events). It significantly boosts shelf visibility and brand presence.

-

Advantage: The 1L packaging can simplify the filling process and reduce the number of units required for transport. It meets the consumer demand for a “one-stop purchase,” potentially increasing the average order value.

2. Premier Printing Aesthetics & Brand Customization (H2)

-

Selling Point: “Your Can is Your Best Billboard.” The generous printing surface provided by the large diameter ($\approx 84.1\text{mm}$) and height ($\approx 204.8\text{mm}$) allows for extensive brand storytelling and detailed graphic representation.

-

Advantage: Supports up to 7 colors of custom printing, utilizing durable, food-grade Epoxy resin inner coatings. This makes the can perfectly suitable for a variety of beverages like beer, juice, and soda, ensuring vivid visual appeal without compromising the product’s safety.

3. Superior Material & Structural Integrity (H2)

-

Selling Point: “Built to Last, Designed for Safety.” Manufactured using high-standard 3004/3104 aluminum alloy, ensuring the can body possesses excellent pressure resistance and deep-drawing formability.

-

Advantage: The combination of high-strength material and precise dimension control (e.g., diameter tolerance of only $\pm 0.01\text{mm}$) guarantees structural stability and seal integrity throughout the filling, retort (sterilization), and transportation processes.

6 Essential Aluminum Can Questions from a Buyer’s Perspective (Human Tone FAQ)

To help your brand move swiftly toward collaboration and technical understanding, here are six key questions you might have, answered in a direct, consultative voice.

Q1: “Isn’t your 1L can excessively heavy? I’m genuinely worried about the transportation costs for such a large package.”

Our Answer: That is an excellent point! While our 1L can offers huge capacity, rest assured that we utilize high-strength 3004/3104 alloy combined with advanced DWI (Drawn and Wall Ironing) techniques. This ensures the can wall is as thin as possible, achieving lightweight design despite its size. We optimize every gram of weight without sacrificing integrity, which directly translates to savings on your bulk shipping and logistics costs.

Q2: “My craft beer requires sterilization. Can your inner lining truly withstand that kind of heat?”

Our Answer: Absolutely! For processes like retort sterilization required by certain juices or craft beers, we specifically apply a food-grade Epoxy resin inner coating. This lining is rigorously tested to handle high heat and pressure, effectively isolating the beverage from the metal. This guarantees that the flavor remains unchanged and that the product is completely safe throughout its shelf life.

Q3: “How many colors can I use for custom printing? I have very specific brand color requirements.”

Our Answer: We understand the importance of color to your brand! Our high-speed printing line supports up to 7 colors for custom printing, which is sufficient for most complex design needs. Crucially, before printing, we provide an accurate color matching service, ensuring the inks used precisely replicate your brand’s standard colors as intended.

Q4: “Will the Minimum Order Quantity (MOQ) for a 1L can be extremely high?”

Our Answer: Given the size and specialization of the 1L can, our MOQ is naturally higher than that of standard smaller cans. For custom-printed cans, the requirement is typically around 250,000 units (per SKU). However, this figure is flexible and negotiable based on your specific project and the potential for a long-term partnership. We aim to find the most cost-effective solution for your batch production.

Q5: “What is the turnaround time from placing an order to actual delivery? I need the goods quickly.”

Our Answer: We maintain one of the most competitive lead times in the industry. Generally, after your deposit is received and the artwork is confirmed, our delivery time is approximately 20 to 25 days. We prioritize streamlining our supply chain to ensure your custom aluminum cans can quickly enter the filling stage.

Q6: “We are a new brand. Can you offer design support, or do you only provide templates?”

Our Answer: We absolutely can! We actively welcome collaboration with new brands. Beyond providing accurate can body templates (like the height of $\approx 204.8\text{mm}$ and diameter of $\approx 84.1\text{mm}$), we can offer professional packaging design advice or layout support. Our goal is to ensure your product not only has a sturdy container but also possesses maximum visual marketing power.